Understanding **Plastic Mold Makers**: Crafting the Future of Manufacturing

The plastic mold makers industry is a cornerstone of modern manufacturing, enabling the mass production of intricately designed plastic parts that are essential in countless applications. From automobiles and electronics to consumer products and medical devices, the molds created by these skilled artisans determine the success and efficiency of production lines. This article delves into the complex world of plastic mold makers, focusing on their significance, processes, innovations, and how businesses like hanking-mould.com set the industry standard.

The Role of Plastic Mold Makers in Modern Industry

At the heart of the manufacturing process, plastic mold makers are responsible for creating the molds used in injection molding—one of the most critical processes in producing plastic components. Their expertise not only streamlines production but also ensures that end products meet stringent quality standards.

What is Injection Molding?

Injection molding is a process where molten plastic is injected into a mold to create specific shapes and designs. This method allows for the production of both small and large quantities of identical parts efficiently.

Key Benefits of Working with Professional Plastic Mold Makers

Choosing the right plastic mold makers can significantly impact your business's success. Here are some key benefits of partnering with professional mold manufacturers:

- Quality Assurance: Professional mold makers prioritize quality, ensuring that every mold produced meets precise specifications.

- Cost Efficiency: By reducing material wastage and optimizing production cycles, professional mold makers help deliver cost-effective solutions.

- Technical Expertise: Their extensive experience allows them to provide valuable insights into design and material choices.

- Innovation: Top mold makers embrace new technologies and techniques, ensuring that their clients benefit from the latest advancements in manufacturing.

- Comprehensive Support: From design to production and beyond, professional mold makers offer support at every stage of the process.

Choosing the Right Plastic Mold Maker for Your Needs

Finding the right plastic mold maker involves several considerations. It’s essential to align your business requirements with the capabilities of the manufacturer. Here are crucial factors to evaluate:

1. Experience and Expertise

Look for mold makers with extensive industry experience. A well-established company, such as hanking-mould.com, often has a proven track record and can deliver high-quality solutions tailored to your needs.

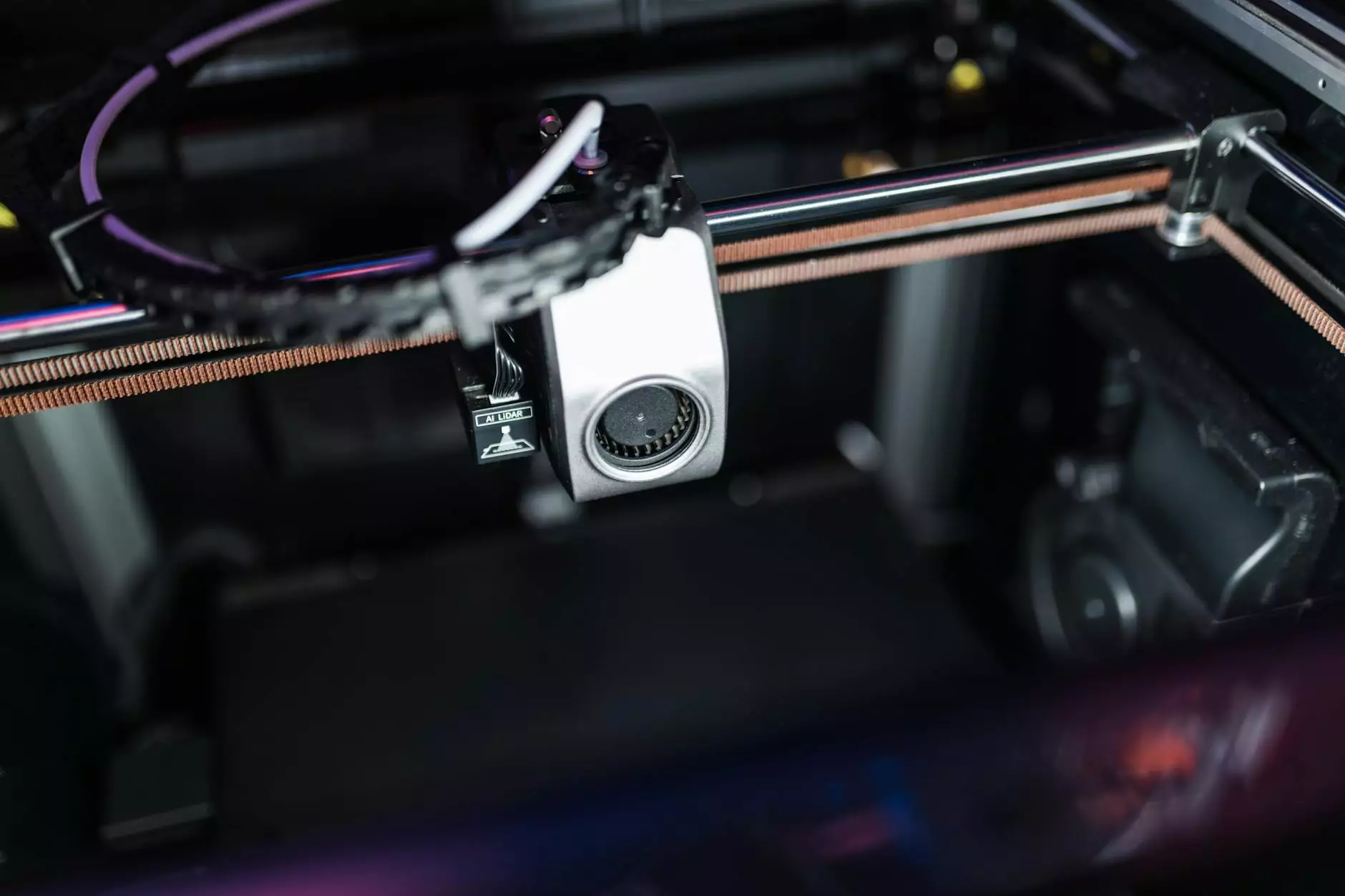

2. Technology and Equipment

Modern mold-making relies heavily on technology. Ensure that the mold maker utilizes state-of-the-art equipment and software for design and manufacturing processes. This can significantly improve precision and reduce lead times.

3. Range of Services

Some mold makers offer a wider range of services, including design assistance, prototyping, and post-production support. A full-service provider can save you time and resources.

The Process of Mold Making: A Closer Look

1. Initial Consultation and Design

The process usually begins with an initial consultation, where the client's requirements are outlined. During this phase, mold makers create detailed designs using Computer-Aided Design (CAD) software, allowing them to visualize the final product before manufacturing begins.

2. Prototype Creation

After finalizing the design, a prototype is often created. This model allows clients to test and validate the design before moving forward with mass production. Adjustments can easily be made to ensure the final product meets all specifications.

3. Mold Fabrication

Once the prototype is approved, the fabrication of the mold begins. High-quality steel or aluminum is typically used to create durable molds that can withstand the injection pressure and produce high volumes of parts.

4. Testing and Quality Control

Before mass production, the mold undergoes rigorous testing to ensure it performs as expected. Quality control steps are implemented to identify and resolve any issues early on.

5. Production and Delivery

Once testing is complete, the mold enters production. The plastic mold makers ensure timely delivery while maintaining quality standards throughout the entire process.

Innovations in the Plastic Mold Making Industry

The field of plastic mold making is constantly evolving, characterized by cutting-edge technologies and innovative practices. Here are some noteworthy trends shaping the industry:

1. Additive Manufacturing

3D printing technology is transforming the design and prototyping phases in mold making. It allows for rapid prototyping and reduces lead times, enabling more flexibility in design adjustments.

2. Smart Manufacturing

The rise of IoT (Internet of Things) in manufacturing has paved the way for smart molds that can provide real-time data and feedback, improving efficiency and quality.

3. Eco-Friendly Materials

With increasing awareness of environmental issues, many mold makers are exploring sustainable materials for plastic production, helping companies meet their green initiatives.

4. Advanced Simulation Software

Modern simulation tools allow mold manufacturers to predict and mitigate potential issues in the mold design and production processes, ultimately saving time and reducing costs.

Common Applications of Plastic Injection Molds

The versatility of plastic injection molds is evident across numerous industries. Here are some common applications:

- Automotive Industry: From dashboard components to exterior parts, plastic molds play a crucial role in automotive manufacturing.

- Consumer Electronics: Molds are used to create casings, buttons, and many intricate components within electronic devices.

- Medical Devices: Precision and reliability are paramount in the medical field, and custom molds are essential for producing high-quality medical equipment.

- Packaging: Many consumer goods rely on mold makers to produce packaging that is both appealing and functional.

- Home Appliances: Molds are fundamental in the production of various household devices, ensuring durability and design consistency.

Conclusion: Why Your Business Should Partner with Leading Plastic Mold Makers

In conclusion, the role of plastic mold makers is fundamental in the manufacturing sector, driving efficiency, quality, and innovation. Businesses that choose to partner with reputable mold manufacturers like hanking-mould.com can lean on their expertise to navigate the complexities of mold design and production, ensuring that they remain competitive in an ever-evolving marketplace.

Embracing the collaboration with skilled plastic mold makers not only enhances product quality but also promotes effective time management and resource allocation—essential elements for scaling your business and achieving long-term growth.

Get Started Today

If you're ready to enhance your manufacturing capabilities, consider reaching out to experienced plastic mold makers today. High-quality molds are just a call away, and your journey to success in the manufacturing landscape begins here.